A sequence of phenomena can occur when metallic/ceramic particles impact metallic/ceramic substrate at supersonic speeds, including deformation, adhesion, melting, erosion, and jetting on the surfaces. Our group specializes in the design and characterization of high speed (up to 0.8 km ) particle deposition systems with application in coatings and in modeling material damage and erosion that may occur during hypersonic flight. These experiments consist of producing particles with diameters ranging from 1 x

m to 1 x

m (10 nm to 100 micrometers) and hydrodynamically accelerating them by use of custom-built converging -diverging nozzles for impact on various material surfaces.

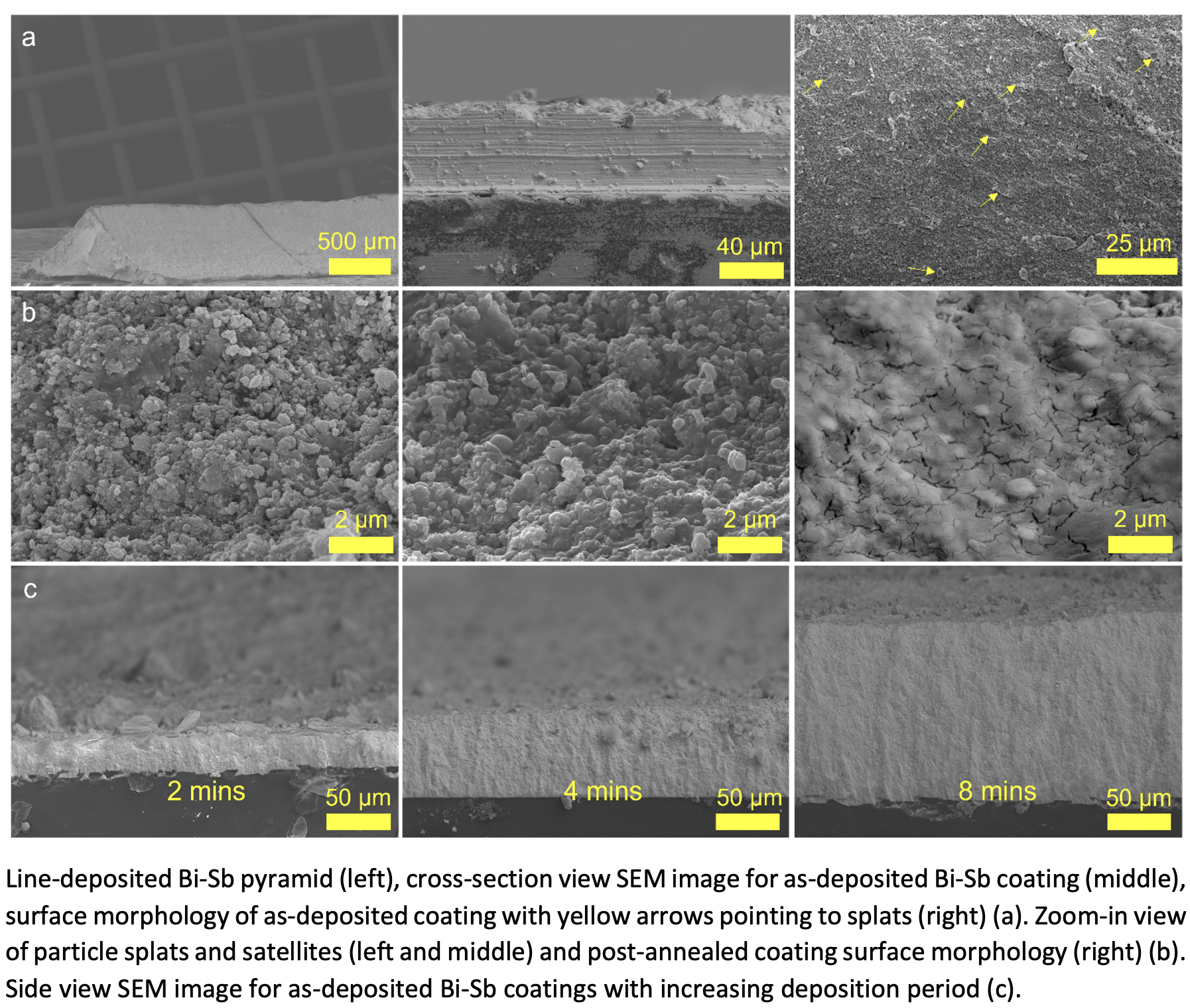

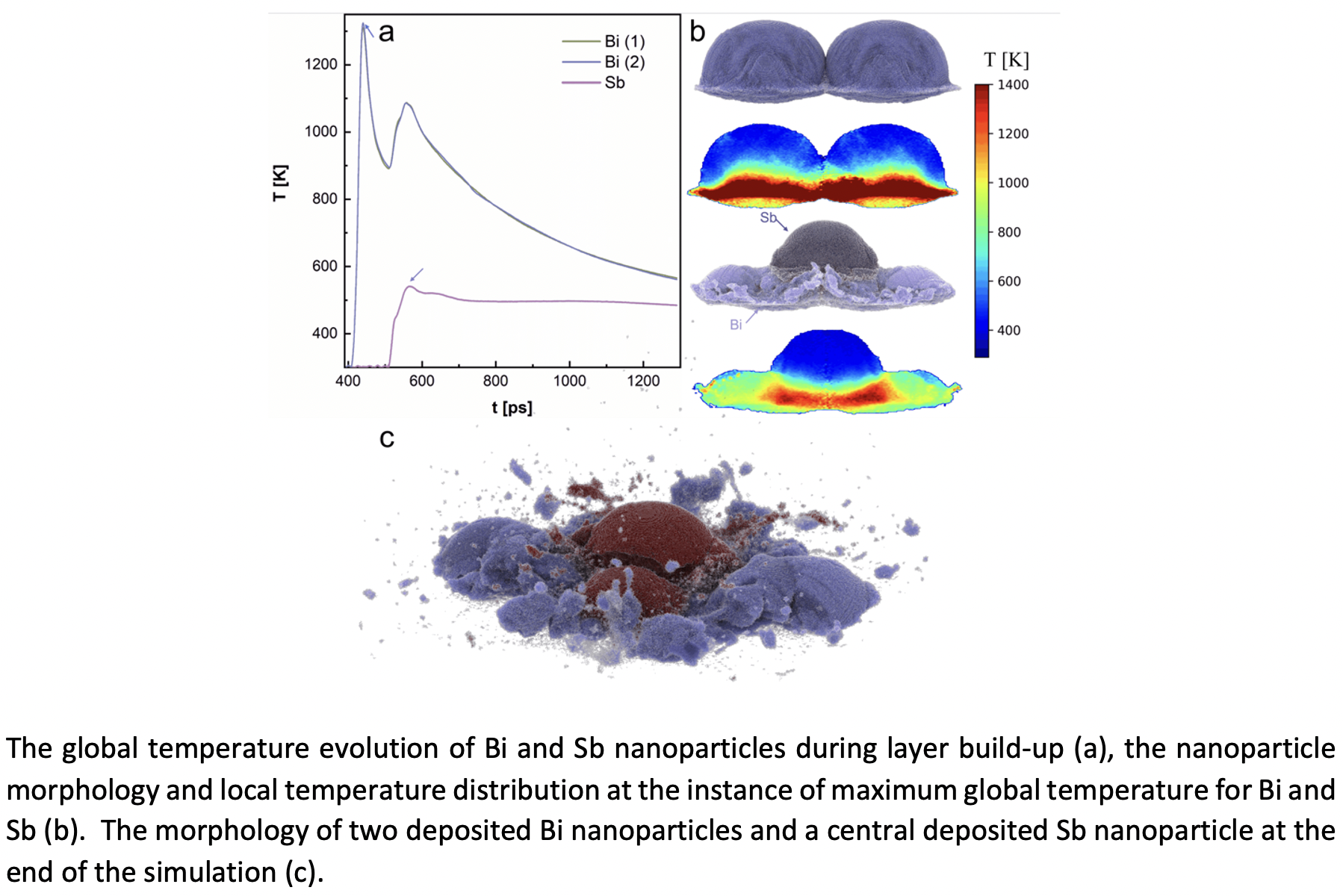

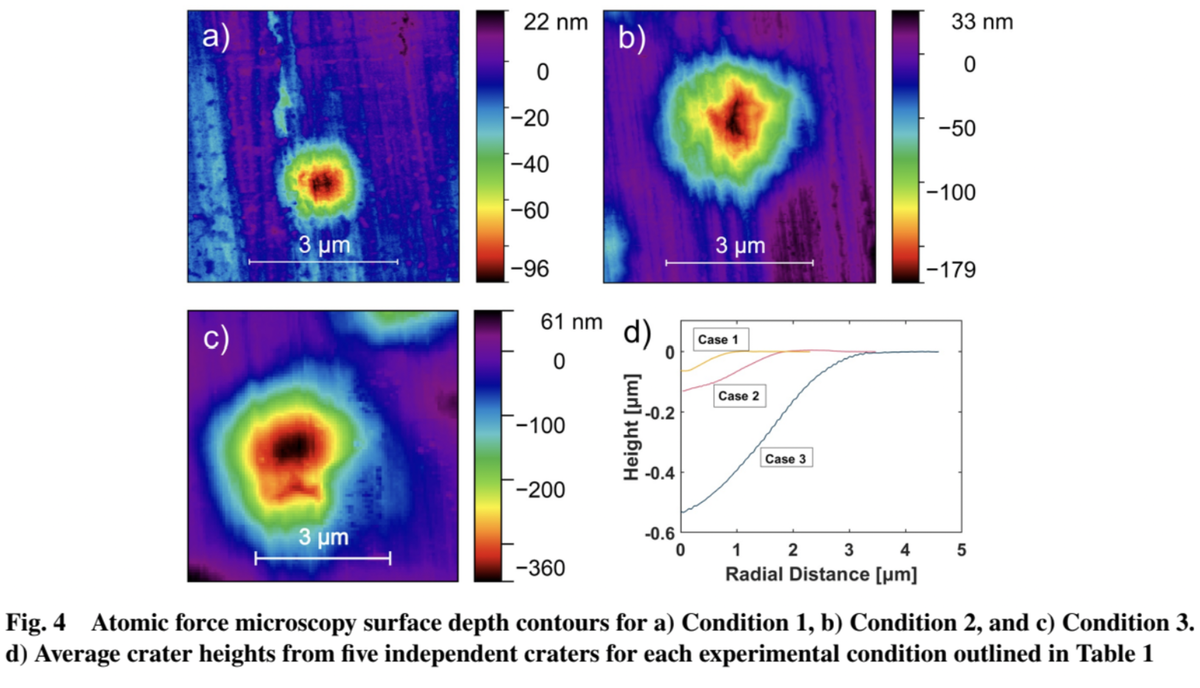

Although small in size, these particles have large impacting kinetic energies allowing for the production of dense thick films if impacted at the proper speed, as well as study of material ablation by micrometer particles during higher speed impacts. Characterization of deposition makes use of a wide range of techniques including Scanning Electron Microscopy (SEM), Focused Ion Beam (FIB), Atomic Force Microscopy (AFM) and X-Ray crystallography (XRD). In support of experimental results, fundamental studies have been conducted on the particle motion and drag in transitional regimes (continuum to non-continuum and supersonic flows) as well as material deformation modeling and investigation of the kinetic energy dissipated by plastic deformation upon impact with the use of molecular dynamics simulations. The MD simulations enable to study the mechanical properties of nanoparticles, i.e., yield strength and hardness, at strain rates on the order of 10-9s-1, which can be achieved by supersonic impact tests.